Case Study: How Future Technologies Enhanced EV Manufacturing with One of the World’s Largest Private 5G Networks Using iBwave

Overview

Future Technologies Venture, LLC, a lead system integrator based in Atlanta, Georgia, specializes in private wireless networks for industrial, government, and military applications. For over 25 years, they have driven connectivity transformations across critical industries. Their recent project involved designing a Private 5G Standalone (SA) network for a Fortune 100 automotive manufacturer in a 5-million-square-foot electric vehicle (EV) manufacturing facility.

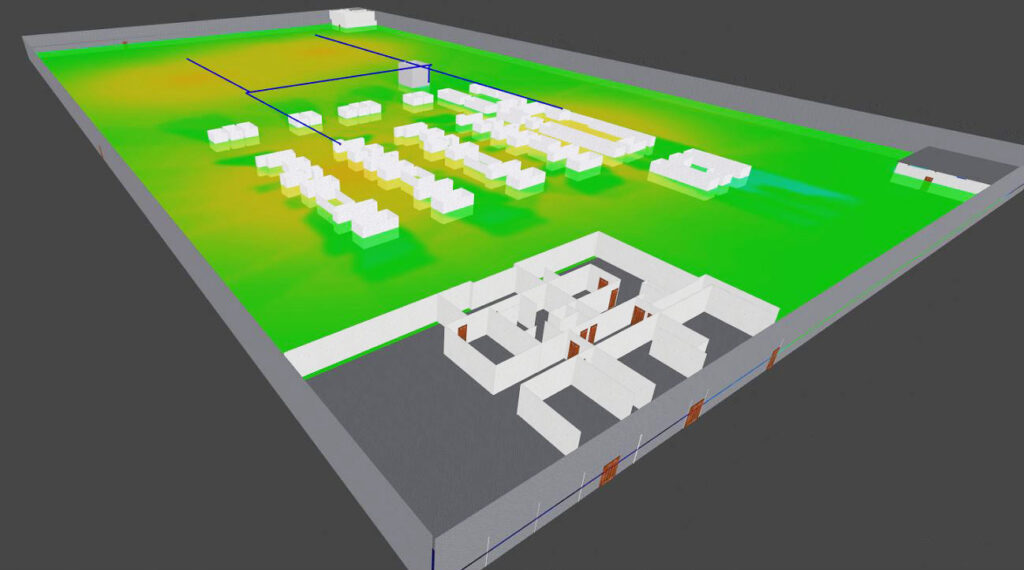

The primary objective was to optimize robotic operations, specifically Autonomous Mobile Robots (AMRs), which are critical to production efficiency. Traditional Wi‑Fi networks struggled with mobility and seamless handoffs, leading to operational delays. Future Technologies leveraged iBwave’s design solutions and their in-house Living Lab for advanced connectivity testing to deliver a high-performance, low-latency Private 5G network that fully enabled AMR operations.

The Challenges

Mobility Limitations with Wi‑Fi

The EV manufacturer relies on AMRs to improve efficiency, but through Future Technologies’ evaluation, it was clear that a traditional Wi‑Fi infrastructure could not support seamless mobility. Frequent handoff issues between access points led to operational delays and inefficiencies, limiting AMR performance.

2Conceptual Design Constraints

Iterative Design Complexity

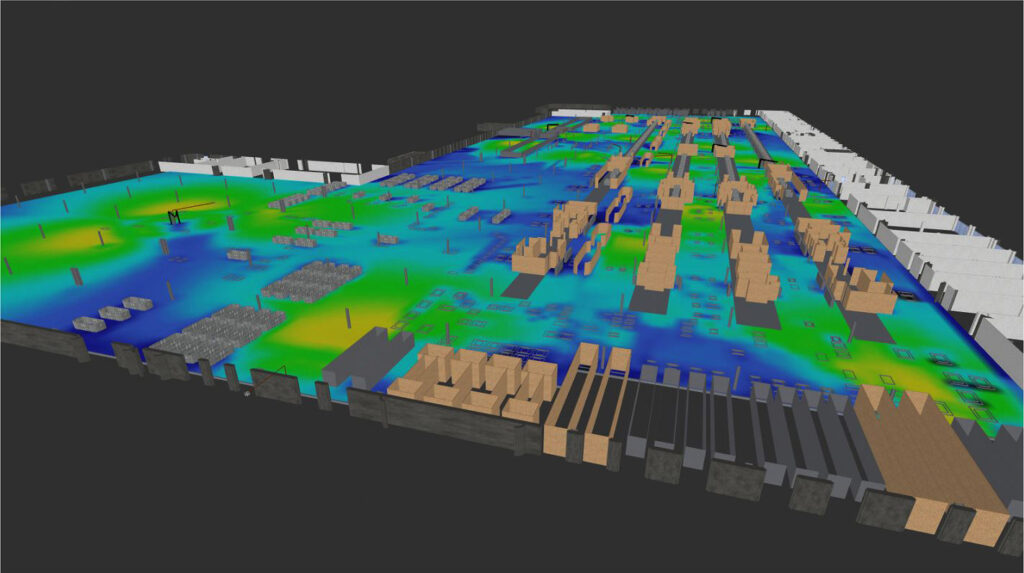

As the facility evolved, the network design required over 40 iterations to adapt to structural changes. Each phase required integrating new obstacles while maintaining performance standards.

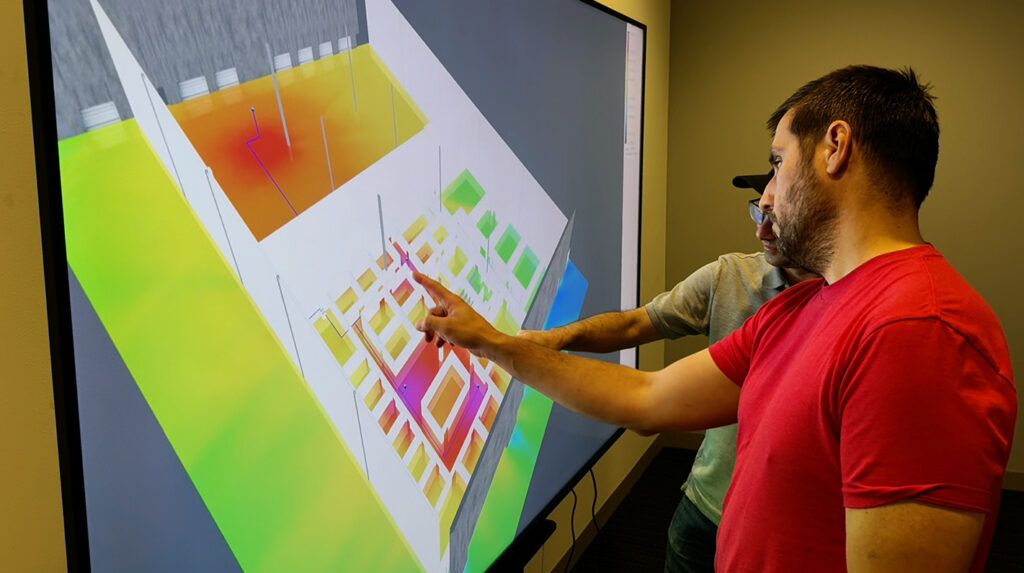

“Our engineering team has 25+ years of experience and access to various tools, but iBwave’s capabilities stood out. It allowed us to model complex environments accurately, iterate through design changes efficiently, and collaborate seamlessly with clients and vendors. This was critical in designing a Private 5G network that fully enabled AMRs, ensuring seamless mobility, low latency, and high performance. The result: a robust network that exceeded expectations.”

– Peter Cappiello, CEO, Future Technologies Venture, LLC –

The Solutions

To address these challenges, Future Technologies deployed a Private 5G SA network, which offered seamless mobility, ultra-low latency, and high reliability. Unlike Wi‑Fi, Private 5G enabled uninterrupted AMR connectivity in high-density environments.

iBwave Design Suite Implementation

Future Technologies leveraged iBwave’s platform to overcome design challenges:

The Results

Seamless AMR Performance and Mobility

The Private 5G network is now commercially deployed and has fully enabled AMR operations by providing seamless mobility, low latency, and high Quality of Service (QoS). The result is a highly reliable connectivity solution that supports real-time AMR navigation without interruptions.

Improved Manufacturing Efficiency

The manufacturer experienced enhanced operational efficiency, with AMRs now operating at full capacity without connectivity-related disruptions. This improved overall production speed and reduced downtime caused by network limitations.

Cost-Effective Deployment

By leveraging iBwave’s detailed simulations, the design process was optimized to reduce costly rework and accelerate deployment timelines, ensuring a cost-effective and optimized deployment that aligned with the factory’s evolving infrastructure.

Want to learn more? Watch our video success story!

Read the Future Technologies’ Press Release for more information about the deployment.